How is combustible dust tested?

Combustible dust analysis consists of a series of tests

both to determine particle size and moisture content,

and to calculate how potentially “explosive” the dust

is. The sampling part is actually fairly simple — dust

is carefully collected using a brush and put into a

glass or plastic jar. It is suggested to collect samples

from the appropriate areas in the production areas and

also from elevated surfaces. A sample consisting of 1

kilogram of dust must be collected and submitted to the

lab for analysis. Air sampling is not necessary to

determine whether or not a dust is combustible.

For combustible dust sampling and analysis, EMSL recommends

following the OSHA ID-201SG sampling method guideline.

The OSHA Combustible Dust Emphasis Program (CPL

03-00-008) also provides information on sample

collection.

Combustible dust is typically

analyzed by a suite of testing:

Initial Dust Characterization

Determines particle size and moisture content. The most

important information determined in this stage are

Percent Combustible Dust. This is the percentage of the

sample that has the potential to be combustible when it

is dry and fine enough to pass through a 40 mesh sieve

(less than 420 μm in size). The testing includes:

• Percent through 40 Mesh Screen

• Percent Moisture Content

• Percent Combustible Material (calculated)

• Percent Combustible Dust (calculated)

Go – No Go Testing (Explosive

Screening) – ASTM E1226

This is an economical and practical way to determine if the

dust in the sample has the potential to be explosive.

Testing consists of exposing the fine dust in the sample

to low energy igniters inside the 20-Liter Siwek

explosion chamber and determine the explosion

overpressure. If the dust is not found to be an

explosive threat, the analysis can be aborted to avoid

unnecessary fees. If the sample turns out to be

explosive on the screen testing, the more comprehend

analyses listed below should be conducted.

Explosion Severity (Kst, Pmax,

[dP/dt]max) – ASTM E1226

This testing provides an indication of the severity of the

dust explosion by determining the deflagration

parameters. The larger the value of Kst, the more severe

the explosion is. For this test, the dust is suspended

and ignited in the Siwek chamber and the maximum

pressure and the rate of pressure rise are measured.

Minimum Explosion Concentration

(MEC) – ASTM E1515

MEC is the minimum concentration for explosivity of a

combustible dust cloud. It is determined by suspending

the dust in the Siwek Chamber.

Minimum Ignition Energy (MIE) –

ASTM E2019

MIE is the electrical energy discharged from a capacitor,

just sufficient to produce the ignition of the most

ignitable mixture of air and dust. It is determined by

suspending the dust in a Hartmann Lucite explosion

chamber.

Minimum Ignition Temperature

Test (MIT) – ASTM E1491 (dust-cloud)ASTM E2021 (dust

layer)

This test method covers the minimum temperature at which a

dust cloud will autoignite when exposed to air and

heated in a furnace at atmospheric pressure. It is

determined by introducing the dust into a BAM oven. As

an alternative, the minimum temperature of self-ignition

of dust layer can be measured using a hot plate set-up.

Class II Testing

This level of testing involves a number of parameters that

determine if the sampled dust is considered a Class II

hazardous material. Class II locations are defined as

locations with combustible dust having Ignition

Sensitivity(I.S.) greater than or equal to 0.2 or

Explosion Severity (E.S.) greater than or equal to 0.5.

I.S. is calculated from MIT, MIE, and MEC for the sample

normalized to Pittsburg coal dust, whereas E.S. is

calculated from Pmax and [dP/dt] max for the sample,

also normalized to Pittsburg coal dust.

Resistivity Testing (for metal

dust in particular)

The resistivity testing is particularly important for metal

dust. The electrical nature of the dust is one criteria

to determine if it is necessary to take special

precaution with regard to electrical insulation of the

equipment operating in a location with Class II dust.

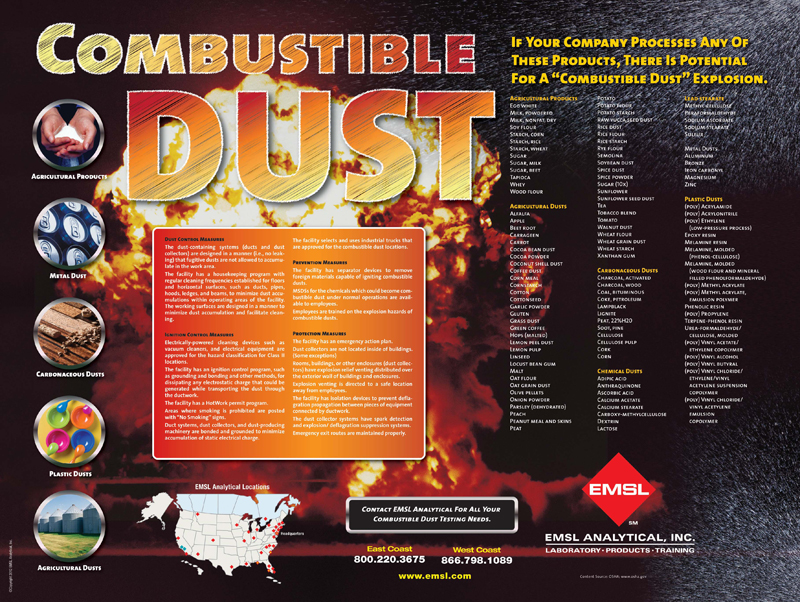

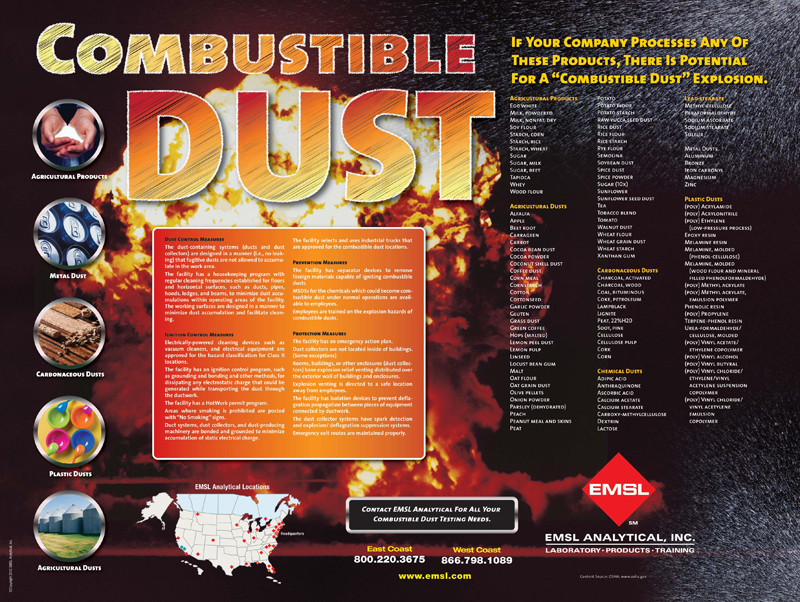

FREE Combustible Dust Poster Page

Download 8.5

X 11 PDF

Request a

16”

x 24” Copy